Technical

The manufacture of dry dog food has advanced considerably over the past thirty years. Nowadays it is a modern, efficient and scientifically controlled cooking process which not only ensures that diets are both microbiologically inactive and can be stored conveniently for long periods of time but are also packed with nutrients and flavours that the cooking process enhances to ensure that your dog will accept and enjoy the food every day.

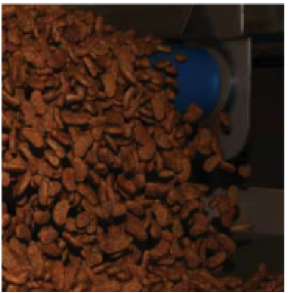

The cooking process for dry dog food is a relatively short one. The raw materials are blended at pre-defined ratios before being ground to specific size particles. These are then extruded into crispy nuggets that are dried and cooled before being coated with oils and natural flavours.

THE SCIENCE OF EXTRUSION

The process of extrusion starts with heating the blended materials in the pre-conditioner prior to introduction to the extruder. The extruder is where the primary cooking phase for dry dog food occurs. The dough is cooked under intense heat, steam and pressure as it moves toward the open end of the extruder. At the end of the extruder, hot dough passes through a shaping die and knife (similar to the action of a meat grinder) where the cut pieces expand rapidly into crispy nuggets when they are under standard air pressure.

There are many variables that affect the cooking process. These can be:

- Environmental (temperature, humidity).

- Within the formulation (high levels of particular nutrients).

- Quality of ingredients, which is why skilled extrusion operators are a combination of engineer and scientist!